Designed in Denmark.

Our philosophy to creation.

Why Design in Denmark?

Design in Denmark is well-known for its simplicity, functionality, and minimalism. Baum's design reflects these qualities with clean lines, natural materials, and timeless looks, resulting in instruments that look and play great.

Why developed in Denmark?

In Denmark, we handle all aspects of product development. We are concept developers, engineers, acousticians, and luthiers.

By crafting the guitars in our custom workshop, we have a deep understanding and full control of their construction to create precise production plans for manufacturers to replicate at scale.

Why manufactured in China?

We choose manufacturing workshops based on their specialization, not their location or country. For the Leaper Stage, we work with Orange Musical Instruments, known for their expertise in handcrafting acoustic guitars and using high-grade tonewoods to make an accessible acoustic guitar with a consistent quality comparable to much more expensive custom guitars.

Why Setup in Denmark?

To ensure top quality, all guitars are brought back to Denmark for inspection, playtesting, and setup. We are picky players ourselves and want to guarantee that each instrument meets our own high standards before shipping them out.

Our process starts in Denmark in our custom workshop, and it ends here. This is our benchmark. This is Baum.

Aarhus, Denmark. We work from a design & production perspective of 80/20. This perspective implies that 80% of the final instrument’s feel and vibe come from the brand, and 20% comes from the manufacturer.

This is why different brands made by the same manufacturer feel and sound different. Because the brand sets its own standards for originality, quality, and vibe.

Baum originates in Aarhus, Denmark. Always. It’s where our first ideas are put on paper, where we build the prototypes, where we constantly evaluate and communicate with the manufacturer, and where the final set-up on each instrument is made.

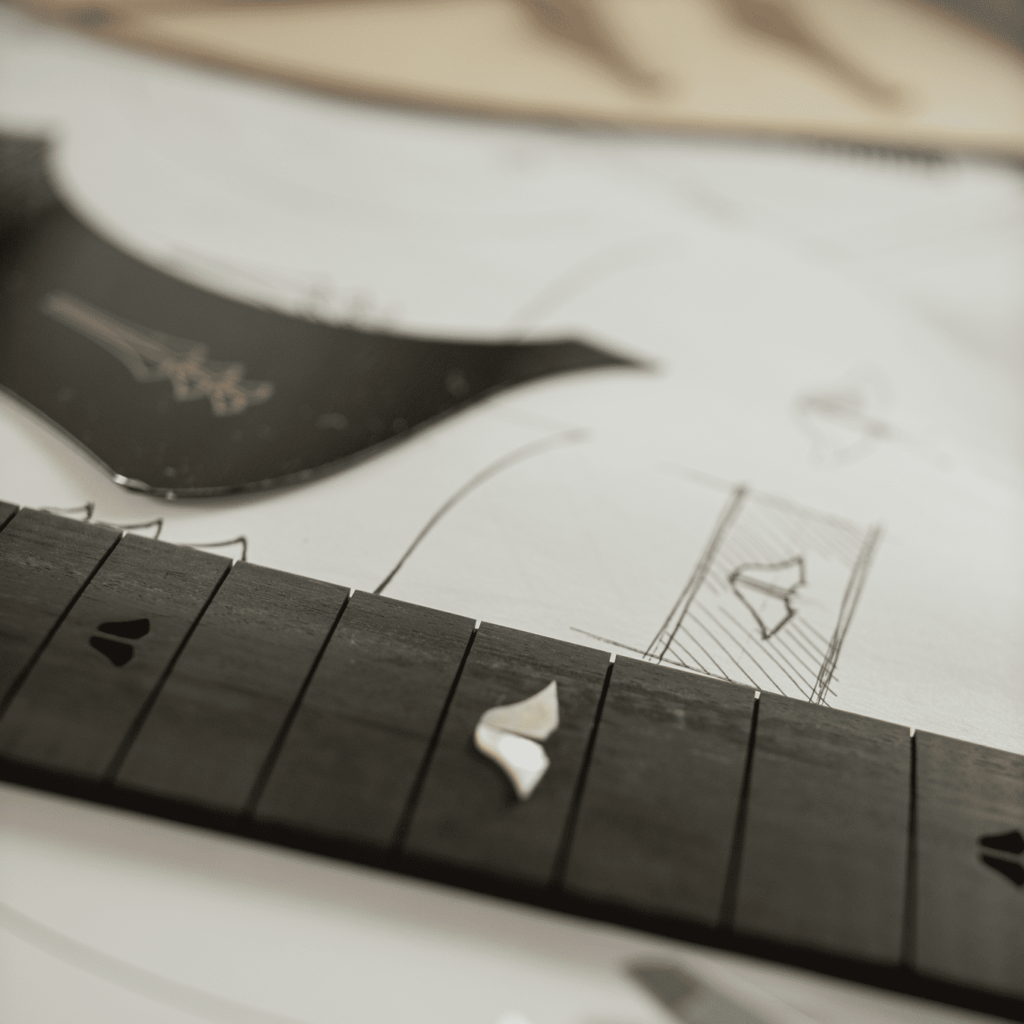

The design

Everything

starts with Architecture.

Aarhus, Denmark. “We start by looking at architecture,” says Morten Bau, when describing the initial phase of any design at Baum, “so we have a general idea of which components and constructions are needed for an instrument to meet our ideas. Form follows function, which simply means that the design is shaped around the functional purpose. And altogether, you get a complete Baum product.”

How: Leaper Stage™

Our inspiration for the Leaper Stage is rooted in the Danish approach to good handwork, minimalistic looks, and inspiring functionalism.

Starting by singling out our preferences for the acoustic sound, we went with a dreadnought shape with a forward-shifted scalloped x-bracing, and a solid-wood construction of rosewood and Sitka spruce to give that rich, resonant, and loud sound.

The integration of nature is a cornerstone in Danish design tradition, and the Leaper Stage is no exception. With inspiration from the admiral butterfly, we integrated its smooth curves in both the Butterfly™ inlays and the Admiral™ bridge.

The Development

Our Know-how.

Aarhus, Denmark. We know the process from sketch to stage very well, because of our decades-long experience as a custom workshop.

We know how tonewood affects the instrument, and how every little detail plays a bigger part in the final experience.

We do everything ourselves. From the early sketches to the design and working drawings, and the 3D plans, we know how these are used in the process of making guitars. Having these skills in-house makes it possible for us to be precise and concise in our daily-to-weekly communication with the individual manufacturer.

This ensures that our work plans match our idea. And that the final instrument matches our mission and vision.

The Production

Communication

is the key.

Manufacturing Partner, Asia. The key to a great product is good communication.

Once the production of a Baum instrument starts, our most important task here is to communicate our know-how to the manufacturer, so they can apply the same approach when building a Baum.

As stated earlier, 20% of the final instruments depend on the manufacturer.

The point indicates that the manufacturer’s most important role is to understand and repeat the design and all its details and make it at the level of quality required by the brand. And it is our most important role to communicate clearly what, how, and why a Baum is.

In other words, the manufacturer should not change anything from our idea.

Guitars made overseas are manufactured by independent workshops.

We spend a long time matching with the right manufacturer with the right knowledge, equipment, and skills, to understand and craft a guitar based on our vision and drawings. And we are involved throughout the whole process communicating and collaborating closely together to ensure that each step is correct before proceeding to the next.

We manufacture guitars and guitar parts in Denmark, South Korea, Indonesia, and China.

How: Leaper Stage™

For the Leaper Stage, we teamed up with Orange Musical Instruments, China, for this very reason. They’re a small workshop with longtime luthiers focusing only on handcrafting high-end acoustic guitars. Likewise, they’re a modern facility with the right tools to meet our high demands for both quality and consistency. Our communication is great and almost daily. This makes them capable of making our acoustic guitars and all their details. And there are a lot.

Lastly, the Leaper Stage is crafted in small batches to ensure the quality of every single guitar. This is not mass production, just quality handwork, and top-shelf guitars.

The Control

OUR OWN QUALITY CONTROL IN DENMARK.

Aarhus, Denmark. All Baum guitars are shipped to Aarhus, Denmark for final quality control and set-up, so we know how it plays before we ship them to you.

What started in Denmark as an idea has now turned into an instrument.

“We are very picky with the quality and playability because we started Baum as a high-end custom shop. And this feeling of a Baum is the benchmark to which we compare all our guitars – custom or production. They’re all the same to us” says Morten Bau, “from a player perspective we have to deliver at the highest level, but that has always been a given, so it is not something we talk that much about. Perhaps we should,” he adds thoughtfully.

We take all guitars to Aarhus, Denmark to ensure that what we have in our hands matches what we have in our minds and what’s on our drawings.

Likewise, we handle our own quality control and give each guitar a good set-up, all to make sure that only guitars that live up to our Baum standard leave our workshop in Aarhus, Denmark.

We are picky players too.

Welcome to the Baum Family.